Capstoning!

Yeah, well, the past 3 days, 16 hours a day, have been a blast. It was quite an experience, testing everything and writing the report and presentation in 1 day. I usually don't set things off so late, but once couldn't hurt!

Just got back from our group presentation, and you know what, it went over awesome! The profs exclaimed, "you guys should go to grad school".

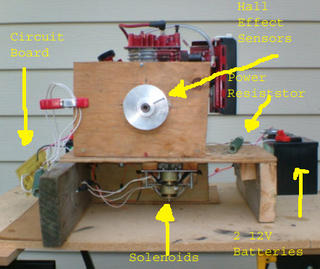

Even though our engine isn't running. Essentially, our control system functions perfectly, and that's all we promised to do. The limiting factor are the solenoids currently on the market (trust me, we bought the best ones possible.). They just can't "give 'er " enough (to quote Fubar). Although, for our proof of design on Friday, we are considering changing the valve springs so the solenoids will open quicker. This may get the engine to start, 'cause she sure does try. Doing this will limit the engine speed, however, it's not like ithe engine is going to reach a high engine speed anyway due to the solenoid response times :)

Research underway by various automotive suppliers uses custom designed electromagnetic linear actuators. No specs have been given, but my guess is they use better manufacturing processes to increase the # of turns (F=N*I where N is the number of turns) on the solenoid stator to get many times the force characteristic at similar power levels to the top-of-the-line solenoids we used.

2 Comments:

Cool project. I heard they are getting killer results on indy cars using solenoids instead of a cam shaft.

Is there a delayed solenoid facing the opposite way to help the spring kick it closed faster?

There's no solenoid that fires in the opposite direction. We didn't have too much of a problem with the closing times. Those should have stayed approximately the same as when the camshaft was in the engine (since we kept the stock springs.)

In a super high performance engine like the indy's, you'd probably need the kick back solenoid to prevent valve float at high rpm. In fact, I bet those engines would get the most bang for your buck with variable valve timing. I heard they used pneumatic solenoids. That must be cool :)

That's a good idea, though. 2 solenoids or a dual directional solenoid could also be used instead of a spring, which we considered, but then, you're adding twice as many solenoids per valve.

I believe the "custom" linear EM actuators under development have a built in "return coil". They must use some mighty strong magnets/coils on those things.. :)

Post a Comment

<< Home